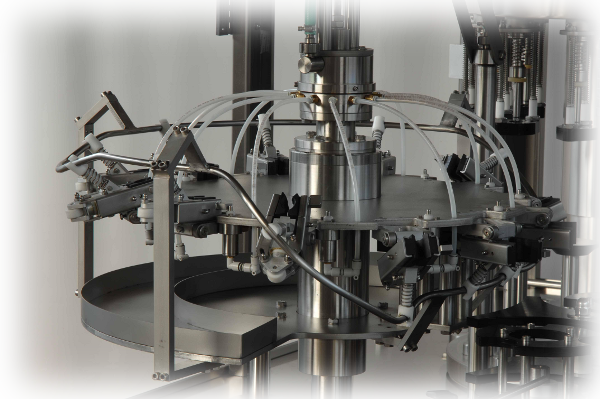

10/10/1S corking Uniblock

Our Uniblock represents the ideal solution for whom needs a complete bottling solution, including rinsing or blowing, filling and capping (or corking) the bottles. To it other elements can be added as needed (such as a labelling machine) to reach the ending product.

As for the filling machine, it is available with different filling system, changing with the density of the liquid: gravity filling, low vacuum filling, vacuum filling.

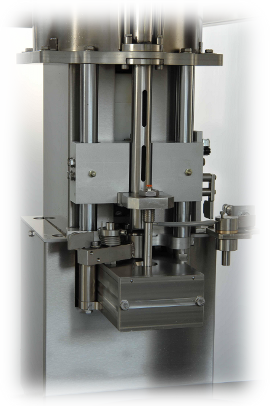

While the corking systems are built upon a single corking head, screw capping systems needing higher productions can be built with a rotative system with more than one capping head.

The liquid level into the machine is set by mechanical spacing rings, which form a simple and accurate way to control the filling phase.

The machine is built upon a solid inox steel basement, except for the base plate, which is anyway covered with inox steel too.

The control panel is made of inox steel and is attached to the machine covering. Speed control is made with an inverter.

The machine is complete of CE-compliant security protections.

10/10/1S corking Uniblock

(Detail) Rinsing turret

(Detail) Corking head for straight corks